This is the final installment in our five-part series, “The Great Farm and Food Talent Search,” a look at the workforce issues facing American agriculture.

Mechanization is the answer to rising H-2A wage rates and labor shortages for Jim Saunders, who’s in “expansion mode” on his central Virginia nursery and fruit farm.

He’s purchased three mechanized pruners over the past three years, and he is looking to purchase another two machines this winter that can prune about three times faster than hand shears as they move on tracks between his rows of boxwood trees. Each machine costs $30,000, but Saunders thinks it's worth it.

“I’ve seen that machine operate, and it’s much faster than our hand pruners. And the machine doesn’t get tired as the day goes on,” he said.

Saunders farms on the eastern side of the Blue Ridge Mountains where he grows peaches, apples, Asian pears and landscape shrubs and trees. He employs 110 foreign, H-2A workers and hires another 100 domestic workers who serve in administrative, accounting, truck driver and supervisory roles. His labor costs have increased 25% since 2019, making mechanization more appealing.

He’s looking at installing robots in his greenhouses to space, prune and fertilize the plants. The potting process is already mechanized so workers don’t have to bend over as much. Still, mechanization remains especially challenging in his business, because fruit can be damaged and ripens differently.

“We’re hopeful that robotics and mechanization is going to reduce our labor. That’s the ultimate goal,” Saunders said.

As the costs of technologies go down and labor costs go up, farmers in all segments of agriculture see mechanization and artificial intelligence as opportunities to stay ahead.

The use of semi-automated technology such as assisted steering continues to become more widely adopted, and the transition to fully automated systems such as weeding robots and computer-operated grain carts is here or soon on the horizon.

Still, the cost of developing and purchasing technology remains steep for many commodities, prompting the specialty crop sector to push Congress this year to provide dedicated funding in the next farm bill for research and cost-share assistance.

Zachariah Rutledge, assistant professor and extension economist at Michigan State University, said his survey of 1,300 farmers found that two-thirds have already adopted a new labor-saving technology due to rising labor costs and shortages of workers.

McKinsey & Company’s 2022 Farmers Global Insights Survey found that 5% of farmers in Asia, Europe, North America and South America were using next-generation technology, compared to 21% using farm management software. Further adoption will be pushed by on-farm economics as well as a desire to implement more sustainable farming practices.

Michael Marsh, president and CEO of the National Council of Agricultural Employers, said the speed and cost of technologies at which operations can adopt mechanization will determine whether many producers will stay in business.

“I don’t think technology adoption can come quickly enough and low cost enough to keep some of these legacy family farming operations in business,” Marsh said. Still, he fears the needed technological innovations will be out of reach for many of farmers and ranchers, who may be forced to leave the business or switch to other less labor-intensive segments of agriculture.

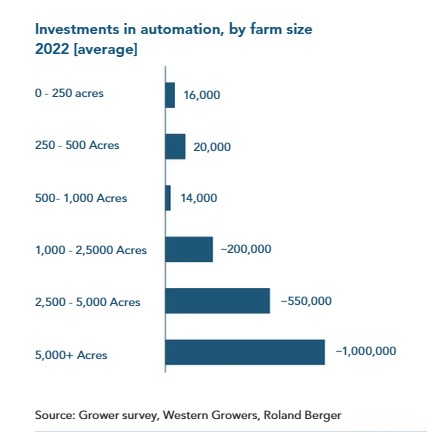

Western Growers’ research on specialty crop automation found that about 70% of participating growers had invested in automation in 2022, with an average annual spend of $450,000 to $500,000 per grower. That's up from 2021 when average investments in automation were around $350,000 to $400,000 per grower.

When growers were asked how they expect automation project spending to change in the next three to five years, “around 40% of growers predicted an increase of 10-50%, while around 30% expected it to rise by more than 50%,” the automation report said.

Walt Duflock, Western Growers' vice president of innovation, said new money is flowing into the agricultural robotics and mechanization space because of labor concerns. While many procedures for processing frozen or packaged fruits, vegetables and nuts are already heavily mechanized, the specialty crop industry is “striving for the last mile for whole fruits and vegetables,” he said.

“I think we’re going to continue to get better at weeding, thinning, planting and harvest-assist that helps the crews out. I think harvest will be the last mile,” Duflock said.

Harvest machines exist today for the types of produce that are easiest to mechanize. Those include blueberries, raisin grapes and baby leaf lettuce. Fruits and vegetables that bruise easily or don’t ripen uniformly, including strawberries, table grapes, fresh market tomatoes and melons, are harder to harvest mechanically.

Tom Gradziel, professor and plant geneticist at University of California, Davis, said mechanical harvesting technology is improving with the many engineers working alongside growers on finding solutions and utilizing the new computing capabilities and image analysis for robots. Adoption will be driven by the economics to achieve a return on investment. Fresh peaches, apricots, cherries and fresh plums pose a challenge because the fruit is tender and matures at different times, he explained.

Robots today, with the support of very efficient computerized systems with high-resolution cameras, can identify fruits that are ripe and selectively harvest only those. “It’s going to be costly, but costs are coming down rapidly. AI is going to help a lot with that,” Gradziel said. “Within the near future, we’re going to have systems that could be effective in your orchard, whether they’re cost effective is going to depend on the cost or the value of that crop.”

Western Growers launched the Global Harvest Automation Initiative in February 2021 with the goal of automating 50% of the U.S. specialty crop harvest within 10 years. The organization established a harvest automation cohort that brings together automation startups and helps integrate technical interfaces into the companies’ product road map and assists in establishing a strategy for go-to-market support, field trials and case studies.

Tom Grandziel, University of California, Davis

Tom Grandziel, University of California, Davis“When the startup has to build everything themself — the image library, the artificial intelligence code that converts that image library into a series of actions for a robot and a robot arm moving down the field — that takes a lot of product road map. That’s a lot to build,” Duflock said.

“It turns out the cost of these startups is just too high for the market they’re chasing right now. We’re starting to fix this, but every crop for fresh produce harvest needs its own robot, and that’s not very capital efficient,” Duflock said. “We’re helping them to reduce that capital need and that time to market for their first product.”

Duflock said startups that have succeeded in bringing new innovations to the table have done the best job of understanding where their solution fits into the growers’ environment and what economic questions they should be asking.

“If we know that labor is our biggest scarcity, we can’t miss the labor crew by a day or that crop is lost,” he said. As an example, if a farm can weed more on the front end to make the harvest group more efficient, this may allow harvesting in three days instead of four.

Western Growers invested in helping develop an image library as part of a “Tech Stack” to assist startup companies in identifying crops with high-resolution images through the entire growing stage.

“Any startup anywhere in the world can take this image library off a site called AgML — Ag Machine Learning,” Duflock explained. “They can pull the images down and on Day One, when you understand what you want to build, we can give you the images to design early-stage R&D work and early-stage prototyping. This can save a mechanical startup six to nine months of high-cost engineering time.”

Duflock said the goal over the next 12 to 18 months is to add 20 to 30 of California’s highest grossing specialty crops to the image library.

Paul Mikesell, CEO of Carbon Robotics, has seen increased adoption of his AI-based laser weeding control system that’s been utilized on specialty vegetable farms and the winner of this year’s “Best AI-based Solution for Agriculture” award in the AI Breakthrough Awards program held by AI Breakthrough.

In an interview with Agri-Pulse, he said the company's LaserWeeder machines use cameras, computer vision and deep learning algorithms for automatic weed and crop detection and then utilizes lasers to kill the weeds in farmers’ fields. The company estimates it has killed more than 2 billion weeds. By the end of this year, LaserWeeders will be operating in 17 states and three provinces of Canada.

“All you need to do is tell the LaserWeeder what crop it's supposed to be protecting,” Mikesell said. The equipment has been used so far in onion, broccoli, cauliflower, carrot, garlic, leeks, radishes and chili pepper fields.

With prices for electronic equipment, cameras and computers going down and labor costs steadily rising, the return on investment for a grower is between 12 months to three years, as it saves up to 80% on weed control costs, Mikesell said. The company claims LaserWeeder can kill up to 99% of weeds, weed up to two acres per hour, and eliminate up to 5,000 weeds per minute.

“With all the pressure around access to workers, a solution like ours makes a lot of sense. When you get a good group of workers together, the last thing you want to do is send them out into the field to pick weeds. There’s a lot better stuff that you can do around the farm,” Mikesell said.

Paul Mikesell, Carbon Robotics

Paul Mikesell, Carbon RoboticsGrowers and technology entrepreneurs will get a chance to see a wide range of ag robotics on display and in operation in September when Western Growers, in conjunction with VINE/University of California, Agriculture and Natural Resources and the nonprofit association Global Organization for Agricultural Robotics, hold a 3-day FIRA USA event, following up on the inaugural event held last year.

Row crop shift to more automation coming, but regulatory hurdles remain

Automation is spreading into the row crop side of agriculture as well.

Five primary areas of precision agriculture are growing in acceptance: auto guidance; machine section control to do things such as switching off a planter or sprayer over previously covered area; variable rate technology to determine application rates for seed, fertilizer and crop protection; telematics to provide real-time monitoring of GPS location and routes; and precision irrigation.

In the next one to three years, AGCO plans to introduce for the North American marketplace a fully autonomous grain cart and tractor for use at harvest, an autonomous baler and tractor, AI weed sensing technology on sprayers, targeted fertilizer applications, self-adjusting planter technology and a fully electric small-horsepower tractor.

Unlike other companies in the large farm equipment space, AGCO allows its products to be used as a retrofit on its competitors' equipment, such as a John Deere planter or Case IH sprayer, as well as its own line of equipment with Massey Ferguson and Fendt. But all the major equipment makers are racing toward increased automation in their own product lines.

“Every automated feature that we put in, whether it's on a new machine, or a retrofit solution, is purely based on farmer economic improvement,” said Eric Hansotia, AGCO's chairman, president and CEO.

During grain harvest, an autonomous grain cart can free employees to do other tasks such as driving a truck. AGCO estimated the use of an autonomous grain cart could offer a 33% increase in harvest efficiency and increase net income by 9% for a Kentucky sample operation where AGCO held a technology showcase in June.

AGCO’s Symphony Vision retrofit suite of products uses camera technology and AI to ensure the right pesticide application rate, placement, source and timing to combat weeds. This can help save money for producers and create less potential impact on the environment from overuse or runoff.

Another type of autonomous technology in development by AGCO is a virtual driver baling system, which has a projected 2025 rollout. It includes collision avoidance and windrow detection and guidance.

Automation has run into some resistance in California because of concerns about the impact on worker safety and pushback from labor unions concerned about job losses.

California worker protection laws prevent the adoption of autonomous tractors. Earlier this year the standards board for the Division of Occupational Safety and Health, or Cal/OSHA, denied two petitions for updating a code that would have allowed autonomous tractor use.

AGCO's autonomous baling tractor pauses as it encounters a dog in a field.

AGCO's autonomous baling tractor pauses as it encounters a dog in a field.“If you don't have a human safety operator on that tractor, the risk for something to go wrong to hurt one of the workers who is in front or behind the tractor is very significant,” said Jassy Grewal, legislative director for the United Food and Commercial Workers Western States Council.

However, other states like Arizona are more welcoming to ag automation, which is why the ag technology industry would likely see a more consistent regulatory environment across the country.

“Technology isn’t something we should be afraid of,” said Curt Blades, AEM senior vice president of ag services, in a recent release about the environmental benefits of precision agriculture. “Technology is something we should fully embrace to meet the challenges that are in front of us.”

Blades said four factors will help accelerate adoption:

- State and federal policies that reward innovation.

- Increased farm income to help enable investments.

- Improved infrastructure (such as wireless networks).

- Improved consumer communication to build trust in the science surrounding new technology.

AI also transforming crop technology advice

The world’s view of ChatGPT and use in agriculture has also transformed as companies and the farmers they work with turn to the AI tool to offer additional insight to assist in decision-making.

Barry Scarbrough, Bayer North America's training and development lead, said the company's field sales representatives are integrating ChatGPT to help improve customer relations. Field reps are using the tool to prepare for conversations with farmer clients that will include data analysis.

Bayer is also launching in the next three to six months a new customer relationship manager tool that Scarbrough said is a combination of “old school sales force and artificial intelligence to interact with the customer.”

Meanwhile, some farmers are turning to AI to make agronomic decisions. The same technology that powers ChatGPT is used in a new platform from the Farmers Business Network, Norm, which acts as an agronomic and economic adviser to aid in farmers’ decision making.

Farm management systems and sensors can also integrate AI-powered platforms to help farmers monitor operations in real time. This can allow farmers to track key performance indicators such as crop health, yield outlooks and financial metrics.

Technology utilization in livestock farms also on the rise

In the dairy industry, robotic milking systems have seen a significant increase in adoption, especially as the sector has been unable to utilize H-2A workers because of the program’s limitation to seasonal employment.

Cows visit the robotic milk station to eat, and then the milking robots automatically attach and detach milking cups to the cow’s udders. Sensors then collect information on milk yield, milk quality and cow health. The technology not only saves on manual labor, it also has been shown to enhance milk production and improve udder health.

Mark Rodgers, who owns Georgia-based Hillcrest Farms with 325 dairy cows, decided to install robotic milkers in December 2019 as he looked for ways to bring the fourth generation of his family into the operation.

“To lead the next generation to take over as stewards of our property and our land, we thought it was probably the best move at the time. We knew labor was going to be our Achilles' heel down the road,” he told Agri-Pulse.

The shift allowed his workers to transition to roles that are less physically demanding, with more flexibility.

“Instead of milking cows and doing monotonous work, we’re doing more cow management,” he said.

“We think we can do a better job managing those cows with robotics,” he explained, as it can detect health concerns by evaluating the milk and sending notifications earlier than humans can identify on their own.

Other technologies in the livestock sector help trace animals and provide real-time health data.

HerdDogg’s remote-sensing Bluetooth tags and cloud-based data platform, are used in cow-calf, dairy, beef, bison and feedlot operations to help find sick animals, monitor health and track animal movement.

HerdDogg CEO Andrew Uden said the technology adoption is increasing because there is no longer an adequate labor force for tasks such as walking pens. The data also improves recordkeeping and data collection.

“One of the reasons that we use technologies like HerdDogg’s is so we can turn on the lights of those animals that are sick,” Uden said, but also in normal tracking and monitoring of vitals and health management as well as on the reproductive side. The technology can detect estrous cycles to help the animals breed more efficiently, Uden said.

It can also be used as a training tool for new pen riders who don’t have the animal husbandry skill set. “It frees up our existing cowboys to do their jobs, and spend less time training because we have this tool in the feedyard,” Uden said.

Uden is excited to see how open Application Program Interface (API) platforms continue to advance and allow producers to integrate and share data across platforms and eliminate cumbersome paperwork.

Don't miss a beat! Sign up for a FREE month of Agri-Pulse news! For the latest on what’s happening in agriculture in Washington, D.C. and around the country, click here.

“If I put HerdDogg tags on my cows and calves, that data can now flow into my feedyard via the HerdDogg system or through an open API right into my feedyard management system,” which saves considerable amount of time for his management team to capture data and recordkeeping across the system.

Research supporting new advancements in technology

Because of the growing cost of labor along with the expense of developing and buying high-tech equipment, the Specialty Crops Farm Bill Alliance appealed to Congress this year to include in the next farm bill a $20 million-a-year research program for automation and a new cost-share program for producers. The alliance said 17 of the 20 most widely consumed fruits and vegetables still require harvesting by hand.

Reps. Doug LaMalfa, R-Calif., Salud Carbajal, D-Calif., Max Miller, R-Ohio, and Abigail Spanberger, D-Va., introduced the Specialty Crop Mechanization and Automation Research and Development Program in June to provide the $20 million in annual research funding, prioritizing projects that address the training and retraining of any impacted employees due to mechanization adoption.

Carbajal, the son of a farmworker, said the technological breakthroughs realized in other industries have not made it to agriculture, where handpicking and labor-intensive methods remain the same since he and his dad were in the fields.

“Undertaken in the right way, with guardrails like those included in our bill, breakthroughs in this space will improve the quality of life for our farmworkers, and ensure we have a more sustainable workforce that is prepared to cultivate the farms of tomorrow,” Carbajal said in a statement.

Igino Cafiero, CEO and founder of Bear Flag Robotics, said at the Agri-Pulse Food & Ag Issues Summit — West in June 2023, that a potentially better way to support the development of new technologies is to assist growers with buying the equipment. If the goal is to reduce herbicide use, for example, provide growers a grant to more easily afford technology such as a laser weeder, Cafiero said.

“Market dynamics can drive the incentive instead of funding the research,” Cafiero said.

Igino Cafiero, Bear Flag Robotics

Igino Cafiero, Bear Flag RoboticsWestern Growers continues to see industry collaboration as an important opportunity to advance the knowledge and technology within the automation space including with partnerships with the Washington Tree Fruit Research Commission and California Table Grape Commission.

Ines Hanrahan, executive director of the Washington Tree Fruit Research Commission, said on a workforce panel during USDA’s annual outlook conference in February that growers in her state are pushing researchers to develop modern apple varieties that can ultimately be harvested mechanically.

“We have a nice variety, Cosmic Crisp, that is climate-friendly, but it also lends itself to automation of harvest,” she said.

Researchers created that variety that comes off the tree easier to aid the mechanization and also tastes good and won’t get damaged when harvested by a machine.

Jenny Maloney, global-Americas strategic account manager at Bayer, said her company is developing novel germplasm to breed crops that can be harvested by machines more easily. The company is already doing this in its high-rise broccoli varieties that grow tall with strong, clean stems and visible crowns that are firm and heavy with uniform maturity, more suited for machine harvesting. Bell peppers are another crop Bayer is targeting in its R&D pipeline for labor reduction traits, Maloney said.

“Breeding efforts can improve the consistency of when bell peppers are mature and ready for harvest, which allows more peppers to be harvested at the correct time when using the automation technology. Novel genetics can also increase the efficiency of hand or automated harvested by offering easier fruit detachment from the plant and ensure higher marketable yield through increased post-harvest fruit quality that is robust to the stress of automated harvest,” Maloney said. “While crop innovation projects have long lead times, they are expected to provide notable benefits to farmers in the future.”

Gradziel said because of the “progressiveness of growers in California,” new varieties he's researching today can be in the field in four to eight years that combine solutions from different harvesting options working with the fabricators, ag equipment manufacturers and engineers and combining that with improved genetics.

New type of workers needed in an automated farming future

As robotics and AI advances, the new question everyone is asking is whether humans will be replaced.

Aaron Smith, professor of agricultural economics at University of California-Davis, believes the answer is a firm “no.”

“We’ve never seen mass unemployment follow from advancements in technology, and so I don’t expect that happening in the future either. What does happen is that people change the kind of work that they do,” Smith said as you look back at other major technology advancements in society such as the introduction of tractors and shift from horses or expansion of automation in factories.

Antonio De Loera-Brust, spokesperson for the United Farm Workers, said, “To the extent that technological innovations and automation can make farmworkers’ jobs safer, more dignified, less physically demanding, we’re all for it.”

He said “technology is morally neutral” but the context of the end goal matters whether technology acts as a way to augment the workforce or to discipline workers and displace them. “Do we have confidence that the well-being of the workers is going to be what’s driving innovation or just the profit motive as always? That’s our concern,” De Loera-Brust said.

He added, “The threat of getting replaced is not with robots, it’s getting replaced with H-2A workers, or some other crop, or with food getting imported from overseas.”

Still, Smith said some field workers could potentially lose their jobs because of automation.

“It is going to be very challenging for them to find other rewarding work to be able to do,” he said. “I think we should not ignore the fact that there are people who can get lost in the shuffle.”

The Bureau of Labor Statistics said due to the increased use of mechanization on farms, ag equipment operator jobs will grow much faster than any other ag job sector during the next decade.

The Western Growers’ report noted a shift in tasks performed by employees to integrate automation into operations and upskilling of workers for automated equipment. In 2022, 50% of growers said they had specific employees who had a majority of their time dedicated to the integration of automated investments. “Around 25% of growers had 1-2 employees, 20% had 3-5 employees, and 5% had 5+ employees dedicated to the task,” the report added.

Duflock believes that within 10 years there will be thousands of robots in fields with thousands of tech-enabled workers building, supporting and servicing those robots. “It’s going to be high-tech, skilled workers who have bigger salaries, who will be harder to find and harder to keep because there’s still going to be a shortage of these workers.”

“As repetitive and manual tasks are increasingly performed by robots, human laborers are able to take on more skilled positions concerned with the integration and management of these technologies. This trend will likely continue as automation investments continue to rise,” the report said.

Smith said there will be winners and losers in the push to greater automation at the farm level. The pace of adoption will depend on the level of productivity growth experienced by producers, beyond just the cost savings on labor and technology costs.

“If you can save 3% or 5% on your cost of growing broccoli or carrots, but then you can also get a productivity bump because the robotic weeder is more effective than hand weeding or because it allows you to operate and manage the field differently, that’s going to be a massive boom,” Smith said.

“As growers figure out how to use these technologies to improve productivity, I think we’ll see gains there that are perhaps larger than and outweigh the cost savings that you might get.”

For more news, visit www.Agri-Pulse.com.