U.S. corn wet mills that produce key ingredients for food are seeing their opportunity for growth and a chance to steal back market share from China stifled because of persistent railroad delays that have become the focus of intense criticism on Capitol Hill and the White House.

Corn wet mills are operating 24 hours a day to churn out the starches needed for everything from pizza to baby powder. Thanks in part to pandemic-related delays in ocean freight, U.S. food and other companies are turning to U.S.-based starch to replace what they were once buying from China, but it’s a different supply chain problem that’s throwing a wrench into what should be a coup for U.S. suppliers.

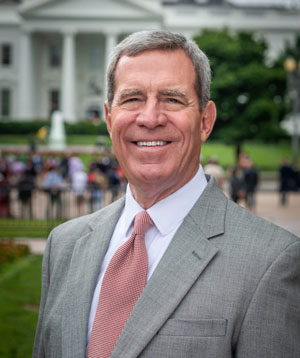

Mills are finding it harder than ever to get their starches to the companies that need them because of dysfunction in the U.S. railroad system that’s only worsened because of the pandemic, says John Bode, president and CEO of the Corn Refiners Association.

“We’ve had a multiyear deterioration of rail service … and with the current pressure in the labor supply, it has gotten far worse," he said. "That disruption has made rail service increasingly unreliable to such an extent that it’s causing significant disruption in the supply chain.”

John Bode, Corn Refiners AssociationIt’s not the kind of disruption the Biden administration wants to see as food inflation continues to rise. Just two months ago the USDA was predicting that grocery prices would rise by as much as 5.5% this year. That’s been raised to 7.5% in the latest forecast released last week.

John Bode, Corn Refiners AssociationIt’s not the kind of disruption the Biden administration wants to see as food inflation continues to rise. Just two months ago the USDA was predicting that grocery prices would rise by as much as 5.5% this year. That’s been raised to 7.5% in the latest forecast released last week.The situation is bad enough that consumers are seeing price spikes on supermarket shelves, but in addition, railroad disruptions are threatening food companies’ ability to get the ingredients they need and then get the finished products to retailers.

The Food and Beverage Issue Alliance — made up of major organizations such as the International Dairy Foods Association, American Bakers Association and the American Frozen Food Institute — says “U.S. rail service failures have forced at least two temporary shutdowns of corn refineries this year, the effect of which is unheard of.”

Looking for the best, most comprehensive and balanced news source in agriculture? Our Agri-Pulse editors don't miss a beat! Sign up for a free month-long subscription.

The plight of the U.S. cornstarch producers is exemplary, says the Bode. The industry is straining to produce at maximum capacity, but then there are no rail cars available to take the product.

“There’s only so many places you can put finished product, so it forces shutdowns,” Bode said. “The shutdowns ripple through the economy in substantial ways because you’ve got numerous products that are used in hundreds of thousands of end products, but suddenly the supply of those ingredients has been interrupted.”

One of the shutdowns of a corn refiner “that supplies essential ingredients to the supply chain” this year cost the supplier $5 million in revenues, FBIA said in written testimony submitted last month to the Surface Transportation Board.

And the escalation of railroad woes comes at a time when the White House and Congress have made improving U.S. competitiveness with China a priority.

With extensive delays in getting starches across the Pacific Ocean, U.S. producers have been willing to step in, scale up and increase supply, Bode told Agri-Pulse.

The situation has become dire enough to prompt a bipartisan group of 21 senators to demand action from the STB.

“We are very concerned over the significant rail service disruptions occurring throughout the U.S. freight rail network,” the senators said in their letter. “Reports from rail customers, including our manufacturers, farmers, ranchers, and energy producers, indicate reliable rail service is not being provided in many situations. In some instances, rail service problems have forced producers to curtail or temporarily stop production altogether.”

The STB has been making progress on solutions it pledged during an emergency hearing that it held in May.

The STB issued an order in early April that requires the four major railroads to begin filing service recovery plans and submit reports on progress in unsnarling their service every two weeks.

But the problems are substantial and one of the worst is the long-standing switching problem, which sends train cars full of product on long detours, delays loading and contributes to forced refiner shutdowns.

Railroads, Bode said, are often not willing to allow cars to be moved from one line to another to provide shipments the fastest possible route to their destinations.

“We’ve got captive shippers,” said Bode. “Often they have only one railroad they can deal with.”

And those railroads are often leaving shippers in the dark about when or if the cars will get on the proper lines.

CRA says mills have contracted for more cars to address uncertain delivery times, but that’s creating a separate problem.

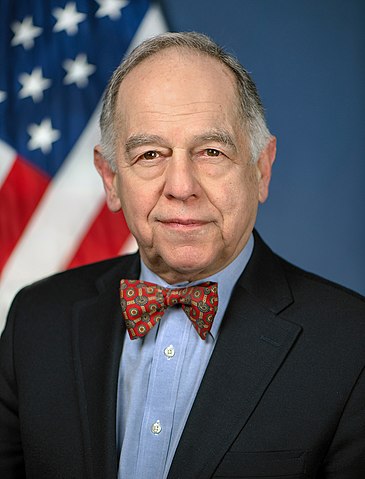

STB Chair Martin Oberman“This has created bunching of cars, increased dwell times and demurrage at destinations," the group explained in testimony to the STB.

STB Chair Martin Oberman“This has created bunching of cars, increased dwell times and demurrage at destinations," the group explained in testimony to the STB.

While the railroads propose that shippers use trucks to ameliorate the problem, Bode says most of the time that’s just not possible.

“The problem is … trucking just isn’t available,” he said. “There’s been a long-standing shortage of truck drivers.”

The STB is scheduled to soon address the switching problem. STB Chairman Martin Oberman said recently he recognized that railroad failures are impacting the economy, but that has not assuaged lawmakers.

“If these problems persist into summer and fall, significant portions of the world’s breadbasket could be cut off from assisting those most in need, yielding waste rather than solutions,” the 21 senators said in their letter.

For more news, go to www.Agri-Pulse.com.